Email: sales@grandcable.cn Tel: +86-510-80711619 Phone:+86-15995373573

English

English

English

English

CU/XLPE/CAS/PE-76/132(145)KV

Grand Cable

| Availability: | |

|---|---|

Description

All cables shall be suitable for operation, at the guaranteed continuous ratings specified, throughout all seasons of the year. The nominal system voltage to which the cables will be connected is 132 kV and the highest operating voltage Um will be 145 kV, respectively.

Cable shall be designed to operate continuously at temperature of 90°C. Each conductor and the metal sheath/screen shall be capable of carrying the specified fault current for the specified time and its final temperature shall not exceed 250°C. Adequate measure should be taken to protect against ingress of moisture and water.

Short circuit earth fault rating of cable metal sheath or metallic screen for 132 kV cable shall be 50 kA for 1se.

The maximum continuous current carrying capacity and maximum permissible conductor temperature, and the factors for determining such rating and temperature, shall be based on IEC recommendation No. 287 and subsequent amendments, and all conditions obtaining on Site. The following conditions for the design of the cables shall be assumed:-

Other conditions for cables laid in concrete ducts/tunnels/buried pipes shall be assumed:

• Max. ambient air temperature: 45°C

• Continuous conductor temperature: 90°C

• Max. conductor temperature under fault: 250°C

Applicable Standard

IEC 60228

IEC 60840

Rated Voltage

76/132(145) kV

Cable Construction

Conductor

Conductors shall be of stranded plain annealed copper wires to IEC or BS filled to make the cables longitudinally watertight by extrusion during stranding. This shall be to prevent ingress of water into the cable should the outer sheath become damaged. The allowable operating temperature of conductor and waterproofing shall be 90°C.

Conductor Screen

Semi-conductive tape for preventing ingress of semi-conductive XLPE and gluing onto the stranded conductors temperature resistance up to 250°C. Semi-conductive extruded cross-linked material to provide a smooth cylindrical equi-potential surface to which the insulation can be intimately bonded. The material shall be compatible in all respects with its conductor and insulation materials.

Insulation

Cross-liked polyethylene (XLPE) melted together with the conductor screen capable to operate at continuous conductor temperature of 90°C and short circuit temperature of 250°C. Cross-linking process using curing is not permitted, dry process shall be given. The insulation of the completed cable shall be substantially free from voids and contaminants.

Insulation Screen

Semi-conductive compound of extruded layer firmly bonded to the XLPE insulation. The conductor screen, the insulation and the insulation screen are to be extruded in a single process to keep the interface smooth.

Metallic Screen

Where the cable core screens are inadequate to meet the earth fault current specified, a metallic layer of adequate cross-sectional area shall be included in the design applied over the screen. The metallic layer shall be Copper screen with counter helix filled with swelling powder sheathed in accordance with latest BS or IEC Publication.

Intermediate Layer

An intermediate layer of suitable compound shall be provided in between metallic screen and aluminium sheath if necessary.

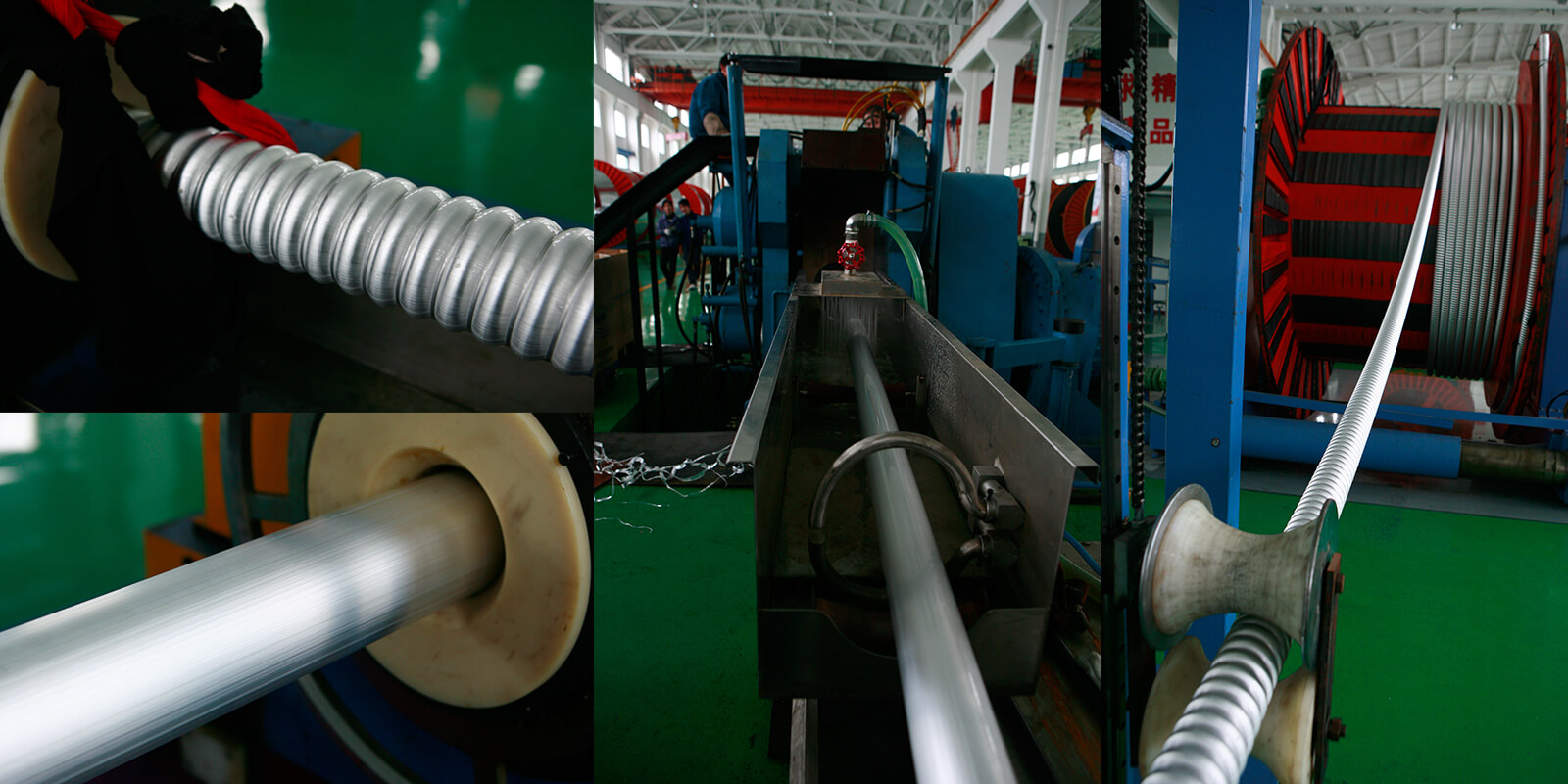

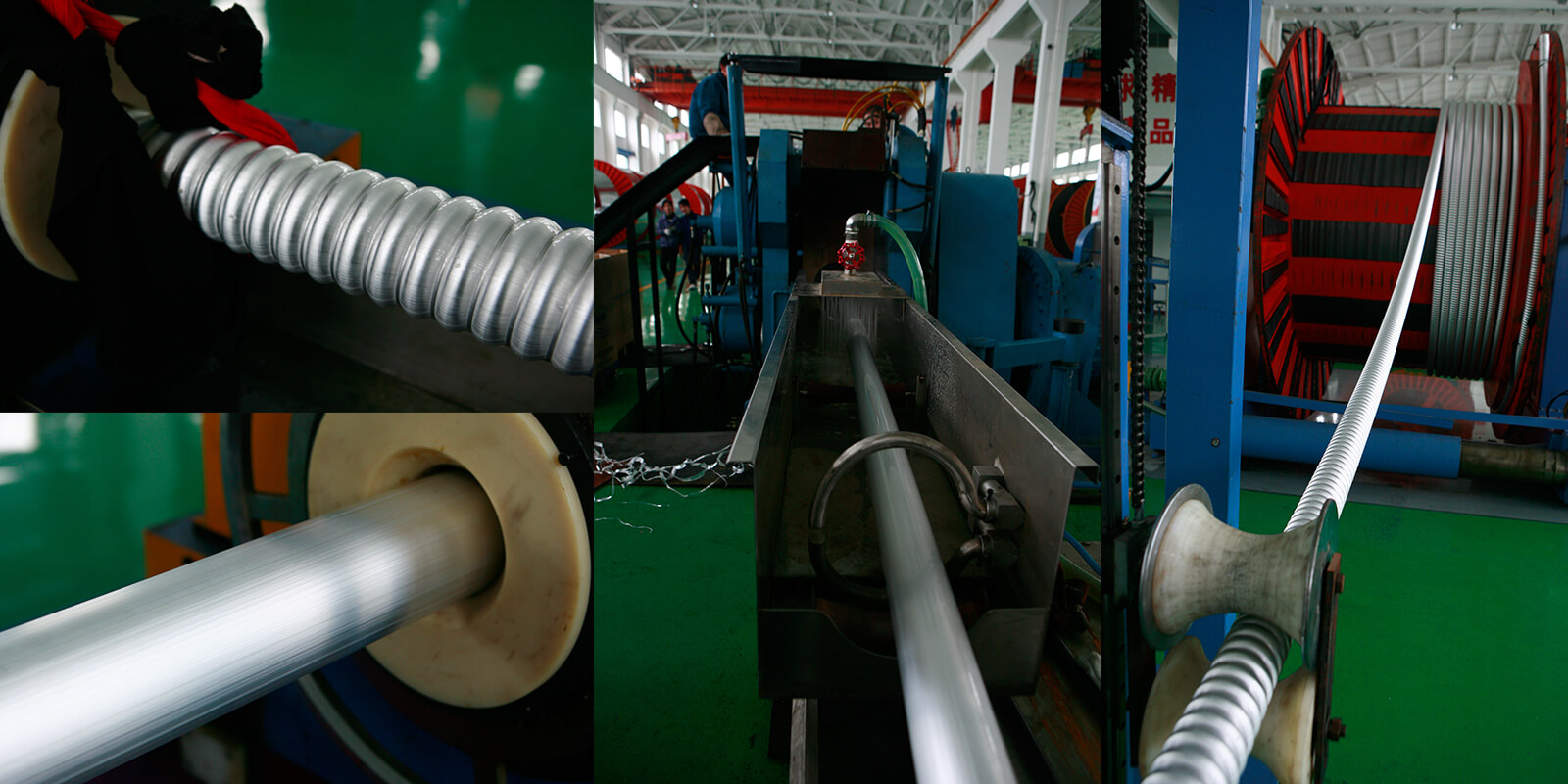

Corrugated Seamless Aluminium Sheath

Metallic sheath shall consist of the extruded corrugated seamless aluminium sheath. Aluminium used for the sheath shall have the minimum purity of 99.5% and shall be of best quality metal free from pinhole flaws and other imperfections. The minimum thickness at any point shall not fall below 85% of the specified nominal thickness by more than 0.1 mm.

MDPE Outer Sheath

After applying the bitumen compound over the aluminium sheath, the extruded MDPE outer sheath shall be applied.

The nominal thickness of outer sheath shall be not less the specified value. The minimum thickness at any point shall not fall below 85% of the specified nominal thickness by more than 0.1mm.

An outer graphite coating shall be applied to outer sheath as an electrode for the voltage test on the extruded outer sheath.

Sealing and Drumming

Immediately after the works tests, both ends of the cable shall be sealed against the ingress of moisture, dirt and insects and the end projecting from the drum shall be adequately protected against mechanical damage during handling. The cable drums shall be arranged to take a round spindle and be lagged with strong, closely fitting so as to take a round spindle and be lagged with strong, closely fitting battens so to prevent damage to the cable. Only steel cable drum shall be used.

The complete cable shall be rolled on steel cable drums capable of withstanding the rough handling during transport without damage of the cable and enabling easy and safe unrolling of the cable during erection.

Each drum shall have marked in indelible point on both flanges, the following indications besides the shipping instructions.

• Destination

• Type of cable

• Exact length

• Net and gross weight

• Trade mark

• An arrow pointing in the direction of unrolling.

Description

All cables shall be suitable for operation, at the guaranteed continuous ratings specified, throughout all seasons of the year. The nominal system voltage to which the cables will be connected is 132 kV and the highest operating voltage Um will be 145 kV, respectively.

Cable shall be designed to operate continuously at temperature of 90°C. Each conductor and the metal sheath/screen shall be capable of carrying the specified fault current for the specified time and its final temperature shall not exceed 250°C. Adequate measure should be taken to protect against ingress of moisture and water.

Short circuit earth fault rating of cable metal sheath or metallic screen for 132 kV cable shall be 50 kA for 1se.

The maximum continuous current carrying capacity and maximum permissible conductor temperature, and the factors for determining such rating and temperature, shall be based on IEC recommendation No. 287 and subsequent amendments, and all conditions obtaining on Site. The following conditions for the design of the cables shall be assumed:-

Other conditions for cables laid in concrete ducts/tunnels/buried pipes shall be assumed:

• Max. ambient air temperature: 45°C

• Continuous conductor temperature: 90°C

• Max. conductor temperature under fault: 250°C

Applicable Standard

IEC 60228

IEC 60840

Rated Voltage

76/132(145) kV

Cable Construction

Conductor

Conductors shall be of stranded plain annealed copper wires to IEC or BS filled to make the cables longitudinally watertight by extrusion during stranding. This shall be to prevent ingress of water into the cable should the outer sheath become damaged. The allowable operating temperature of conductor and waterproofing shall be 90°C.

Conductor Screen

Semi-conductive tape for preventing ingress of semi-conductive XLPE and gluing onto the stranded conductors temperature resistance up to 250°C. Semi-conductive extruded cross-linked material to provide a smooth cylindrical equi-potential surface to which the insulation can be intimately bonded. The material shall be compatible in all respects with its conductor and insulation materials.

Insulation

Cross-liked polyethylene (XLPE) melted together with the conductor screen capable to operate at continuous conductor temperature of 90°C and short circuit temperature of 250°C. Cross-linking process using curing is not permitted, dry process shall be given. The insulation of the completed cable shall be substantially free from voids and contaminants.

Insulation Screen

Semi-conductive compound of extruded layer firmly bonded to the XLPE insulation. The conductor screen, the insulation and the insulation screen are to be extruded in a single process to keep the interface smooth.

Metallic Screen

Where the cable core screens are inadequate to meet the earth fault current specified, a metallic layer of adequate cross-sectional area shall be included in the design applied over the screen. The metallic layer shall be Copper screen with counter helix filled with swelling powder sheathed in accordance with latest BS or IEC Publication.

Intermediate Layer

An intermediate layer of suitable compound shall be provided in between metallic screen and aluminium sheath if necessary.

Corrugated Seamless Aluminium Sheath

Metallic sheath shall consist of the extruded corrugated seamless aluminium sheath. Aluminium used for the sheath shall have the minimum purity of 99.5% and shall be of best quality metal free from pinhole flaws and other imperfections. The minimum thickness at any point shall not fall below 85% of the specified nominal thickness by more than 0.1 mm.

MDPE Outer Sheath

After applying the bitumen compound over the aluminium sheath, the extruded MDPE outer sheath shall be applied.

The nominal thickness of outer sheath shall be not less the specified value. The minimum thickness at any point shall not fall below 85% of the specified nominal thickness by more than 0.1mm.

An outer graphite coating shall be applied to outer sheath as an electrode for the voltage test on the extruded outer sheath.

Sealing and Drumming

Immediately after the works tests, both ends of the cable shall be sealed against the ingress of moisture, dirt and insects and the end projecting from the drum shall be adequately protected against mechanical damage during handling. The cable drums shall be arranged to take a round spindle and be lagged with strong, closely fitting so as to take a round spindle and be lagged with strong, closely fitting battens so to prevent damage to the cable. Only steel cable drum shall be used.

The complete cable shall be rolled on steel cable drums capable of withstanding the rough handling during transport without damage of the cable and enabling easy and safe unrolling of the cable during erection.

Each drum shall have marked in indelible point on both flanges, the following indications besides the shipping instructions.

• Destination

• Type of cable

• Exact length

• Net and gross weight

• Trade mark

• An arrow pointing in the direction of unrolling.