Email: sales@grandcable.cn Tel: +86-510-80711619 Phone:+86-15995373573

English

English

English

English

AL/XLPE/CWS/AL/PE-76/132KV

Grand Cable

| Availability: | |

|---|---|

Applicable Standard

IEC 60228

IEC 60840

Rated Voltage

76/132(145) kV

Cable Construction

Conductor

The conductor shall be circular and stranded and compacted copper or aluminium in accordance with IEC 60228.

The conductor shall withstand the prospective symmetrical short circuit current without exceeding the maximum allowable conductor temperature specified in IEC 60840. The prospective symmetrical short- circuit current magnitude and duration shall be as specified in the technical schedules.

The conductor type and cross-sectional area offered shall be stated in the technical schedules. A barrier shall be provided to prevent longitudinal water penetration along the conductor.

Conductor screen

The conductor screen shall comprise a layer of extruded cross-linked semi-conducting material, coextruded with the insulation and core screen. The nominal thickness of the conductor screen shall be not less than 1.0 mm and the smallest thickness shall not be less than 0.8 mm when measured in accordance with IEC 60811-1-1.

A semi-conductive tape may be used to prevent the extruded conductor screen from flowing into the conductor interstices to facilitate removal of the conductor screen (or both).

Insulation

The insulation shall consist of pure cross-linked polyethylene (XLPE) material fully bonded to the conductor screen.

Core screen

The core screen shall comprise a layer of extruded cross-linked semi-conducting material, co-extruded with the conductor screen and insulation. The nominal thickness of the core screen shall be not less than 1,0 mm and the smallest thickness shall not be less than 0,8 mm when measured in accordance with IEC 60811-1-1.

The core screen shall be fully bonded to the insulation.

Cross-linking of the core screen, insulation and the conductor screen shall be effected in a dry inert gas (nitrogen) pressurized atmosphere.

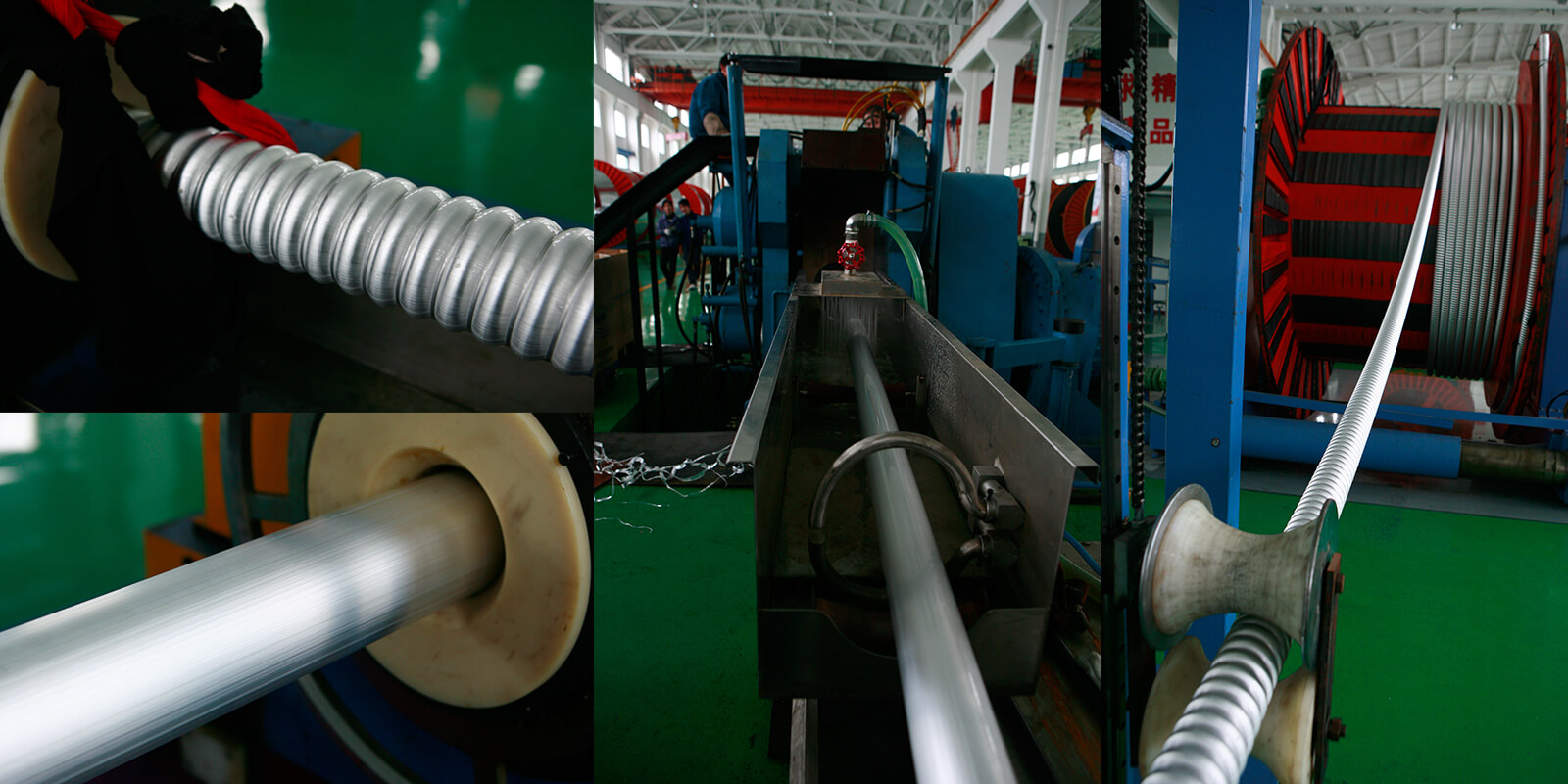

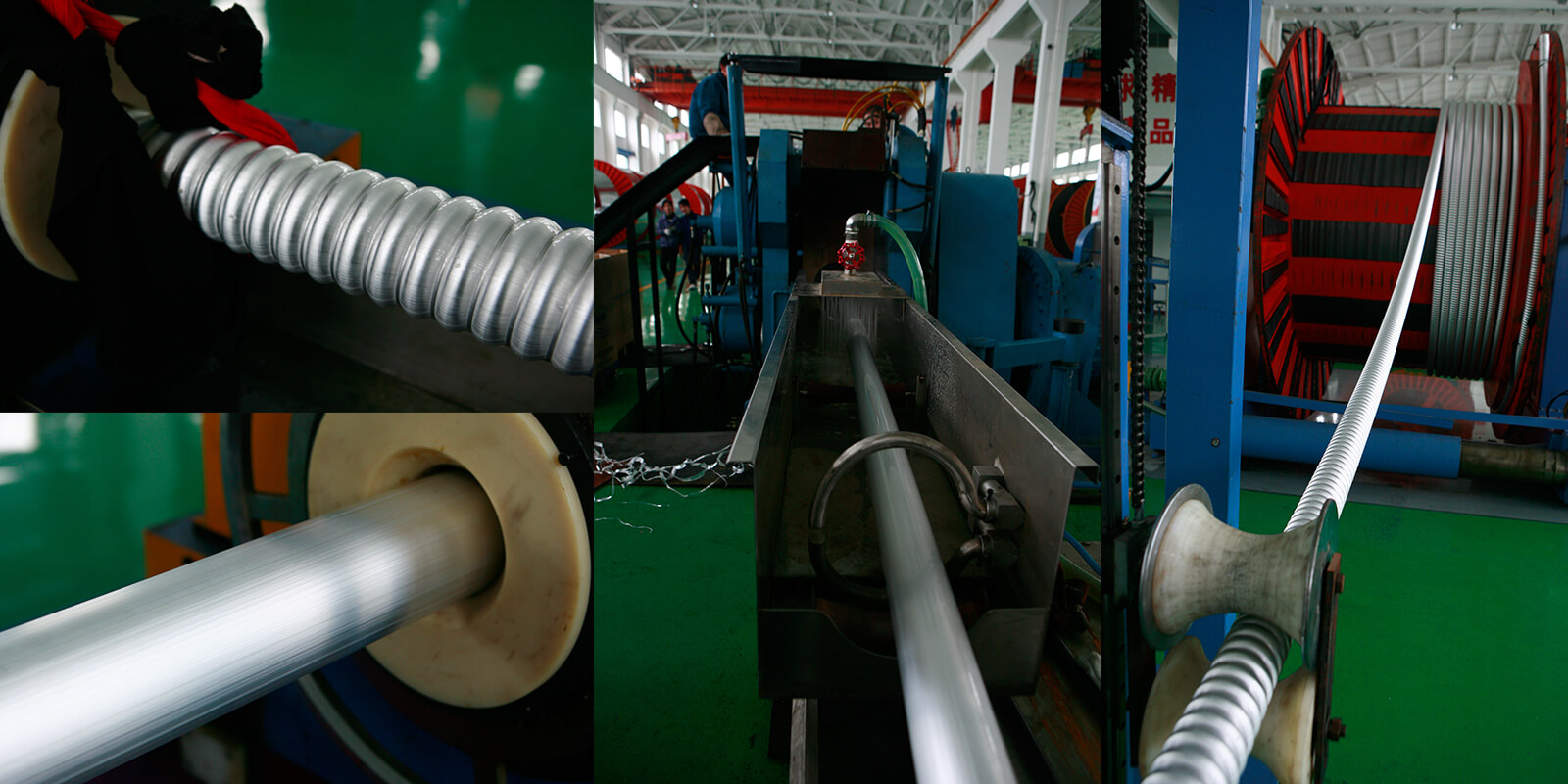

Metal sheath or screen

The cable shall have either a metal sheath or screen of corrugated seamless aluminium, or a copper wire screen with a laminated aluminium/polyethylene sheath.

The corrugated seamless aluminium sheath shall consist of new aluminium of approved origin and purity in accordance with the material grade 1070 A as specified in table 1 of EN 573-3:2009. The sheath shall be free from defects and impervious to water.

The aluminium sheath shall be capable of carrying the fault current specified in the technical schedules, without the temperature exceeding 160 °C.

The nominal thickness of the aluminium sheath shall be stated in the technical data schedules The corrugations shall be of the annular type.

The cable shall have a copper wire screen with an equalizing tape.

The copper wire screen shall be capable of carrying the prospective earth fault current, without the temperature exceeding 200 °C.

A sheath of laminated aluminium/polyethylene foil shall be longitudinally applied and bonded with sufficient overlap as a radial water barrier.

Water barriers

Water swelling tapes shall be included between the core screen and the radial water barrier to restrict longitudinal water travel. In the case of cable that has a copper wire screen, water swellable tapes shall be included below and above the copper wires. The radial water barrier is created by either the corrugated seamless aluminium sheath or the laminated aluminium/polyethylene sheath.

The effectiveness of the applied water barriers shall be confirmed by successful completion of the water penetration test as described in IEC 60840. Details of the water barriers offered shall be stated in the technical schedules.

Outer sheath

The outer sheath shall be an extrusion of black polyethylene type ST7 in accordance with IEC 60840.

The corrugated aluminium sheath type of metal sheath shall have a bitumen or similar material applied to the corrugated aluminium sheath before the outer sheath extrusion to seal the interface between the corrugated aluminium sheath and the polyethylene outer sheath.

The aluminium/polyethylene foil laminate of the wire screen type of metal sheath shall be firmly bonded to the outer sheath.

Applicable Standard

IEC 60228

IEC 60840

Rated Voltage

76/132(145) kV

Cable Construction

Conductor

The conductor shall be circular and stranded and compacted copper or aluminium in accordance with IEC 60228.

The conductor shall withstand the prospective symmetrical short circuit current without exceeding the maximum allowable conductor temperature specified in IEC 60840. The prospective symmetrical short- circuit current magnitude and duration shall be as specified in the technical schedules.

The conductor type and cross-sectional area offered shall be stated in the technical schedules. A barrier shall be provided to prevent longitudinal water penetration along the conductor.

Conductor screen

The conductor screen shall comprise a layer of extruded cross-linked semi-conducting material, coextruded with the insulation and core screen. The nominal thickness of the conductor screen shall be not less than 1.0 mm and the smallest thickness shall not be less than 0.8 mm when measured in accordance with IEC 60811-1-1.

A semi-conductive tape may be used to prevent the extruded conductor screen from flowing into the conductor interstices to facilitate removal of the conductor screen (or both).

Insulation

The insulation shall consist of pure cross-linked polyethylene (XLPE) material fully bonded to the conductor screen.

Core screen

The core screen shall comprise a layer of extruded cross-linked semi-conducting material, co-extruded with the conductor screen and insulation. The nominal thickness of the core screen shall be not less than 1,0 mm and the smallest thickness shall not be less than 0,8 mm when measured in accordance with IEC 60811-1-1.

The core screen shall be fully bonded to the insulation.

Cross-linking of the core screen, insulation and the conductor screen shall be effected in a dry inert gas (nitrogen) pressurized atmosphere.

Metal sheath or screen

The cable shall have either a metal sheath or screen of corrugated seamless aluminium, or a copper wire screen with a laminated aluminium/polyethylene sheath.

The corrugated seamless aluminium sheath shall consist of new aluminium of approved origin and purity in accordance with the material grade 1070 A as specified in table 1 of EN 573-3:2009. The sheath shall be free from defects and impervious to water.

The aluminium sheath shall be capable of carrying the fault current specified in the technical schedules, without the temperature exceeding 160 °C.

The nominal thickness of the aluminium sheath shall be stated in the technical data schedules The corrugations shall be of the annular type.

The cable shall have a copper wire screen with an equalizing tape.

The copper wire screen shall be capable of carrying the prospective earth fault current, without the temperature exceeding 200 °C.

A sheath of laminated aluminium/polyethylene foil shall be longitudinally applied and bonded with sufficient overlap as a radial water barrier.

Water barriers

Water swelling tapes shall be included between the core screen and the radial water barrier to restrict longitudinal water travel. In the case of cable that has a copper wire screen, water swellable tapes shall be included below and above the copper wires. The radial water barrier is created by either the corrugated seamless aluminium sheath or the laminated aluminium/polyethylene sheath.

The effectiveness of the applied water barriers shall be confirmed by successful completion of the water penetration test as described in IEC 60840. Details of the water barriers offered shall be stated in the technical schedules.

Outer sheath

The outer sheath shall be an extrusion of black polyethylene type ST7 in accordance with IEC 60840.

The corrugated aluminium sheath type of metal sheath shall have a bitumen or similar material applied to the corrugated aluminium sheath before the outer sheath extrusion to seal the interface between the corrugated aluminium sheath and the polyethylene outer sheath.

The aluminium/polyethylene foil laminate of the wire screen type of metal sheath shall be firmly bonded to the outer sheath.